For anyone interested I own a 2014 i3 BEV still going strong at 78k miles.

Range is still the same i.e 100 miles give or take and everything works fine except the engine mount which was leaking and broken..

This is actually subject to several recalls in the world i.e EU etc,.. but not in the US.

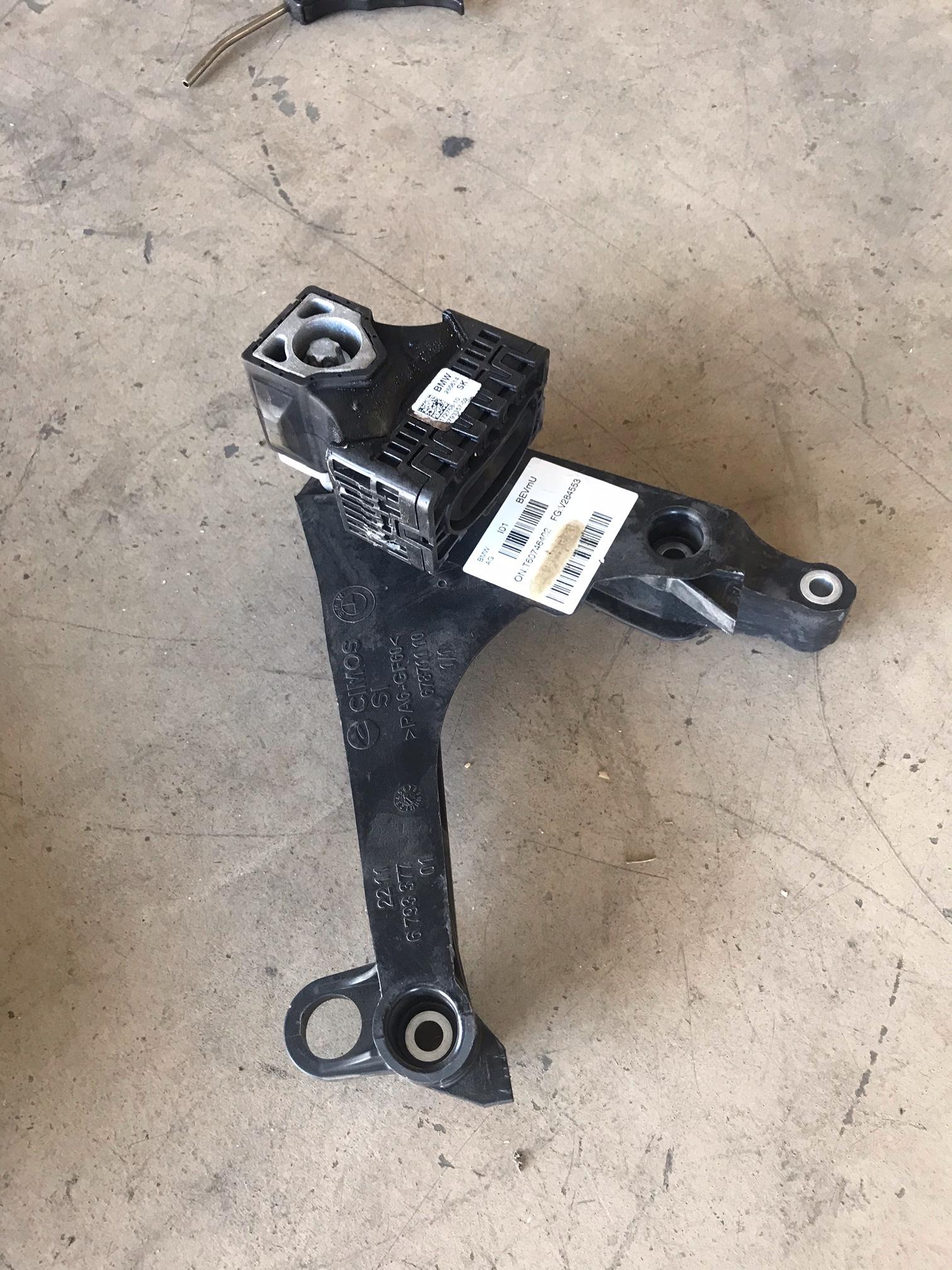

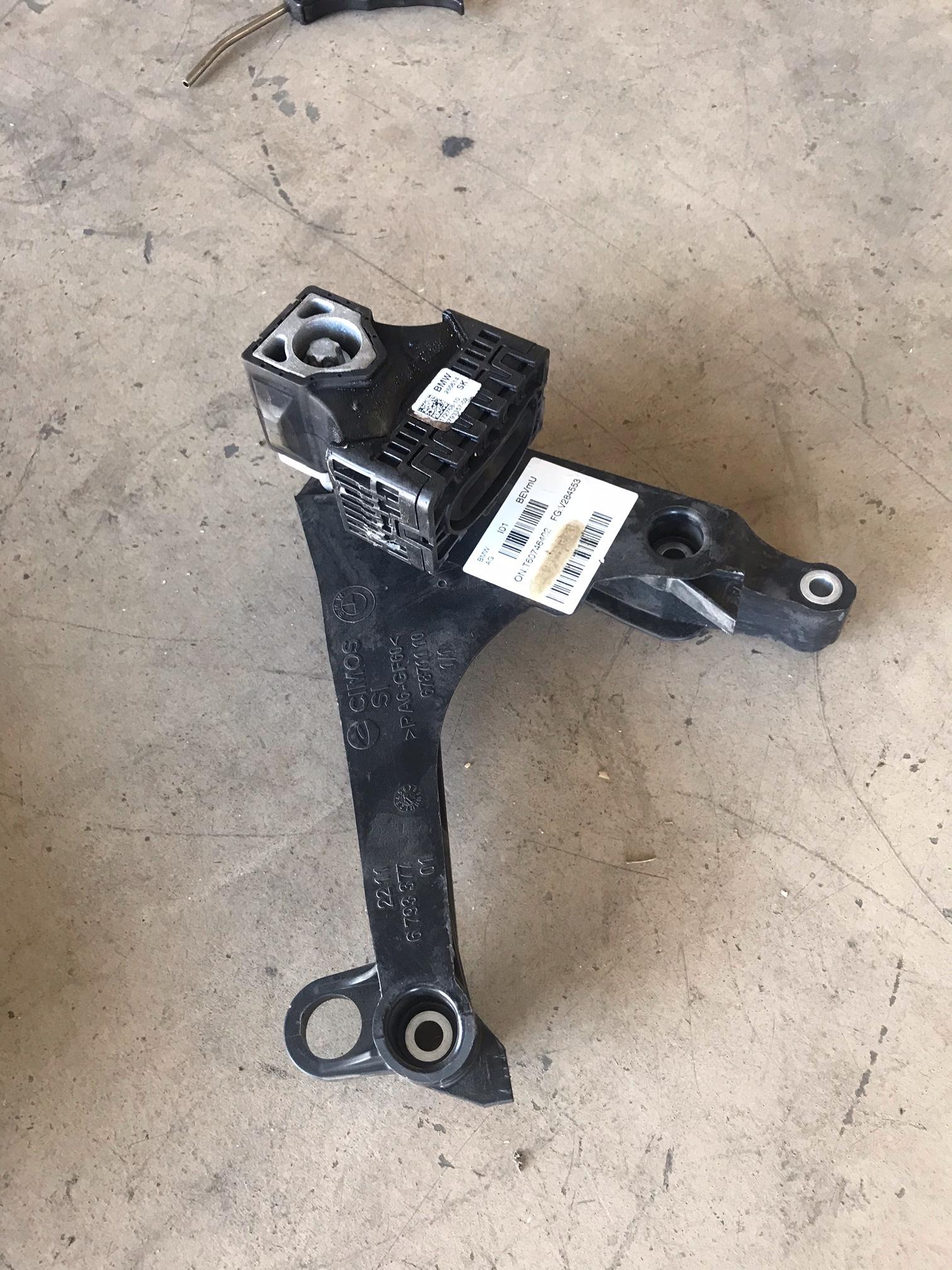

Dealer quoted me a cool 2.7k since the only replacement mount that exists is for a new bracket made out of cast aluminium vs. plastic for the old one. And the only way to put that together is put the new bracket in and that implies literally dropping the whole engine out for the task.

I refused to pay for it arguing it was an original and flimsy design flaw acknowledged by BMW through their subsequent replacement of said bracket by a metallic one with a reinforced bolt and contacted customer service at BMW regarding the matter. But they argued they have no obligation since my car is out of warranty. They suck and I will consider further options.

Meanwhile me and a friend IA (Inspection Authorization mechanic for Airplanes, the highest ranking certification for airplane mechanics) decided to look at the issue and after I ordered the new bracket, mount and new bolt for the setup (Thanks bmwparts.com!!!) we realized the bracket could potentially be removed from the top of the engine and holes drilled in the frame at strategic locations to access the 2 bolts unreachable by design.

This was all risky and a jump into the unknown of course as I had no clue if the bracket had other hidden attachments and the IA had no experience working on a BEV and could only count on his aeronautical instincts.

There's a lot of craftsmanship and creativity that goes into plane maintenance and it definitely came in handy here.

To drill the 2 holes we inferred the location assuming some movement of the engine would be possible after the mount was removed through the weakest spots in the frame on the left and used a 1 in drill bit for the feat.

After removing all the bolts and supporting the engine using its own jack besides the one allowing for tires and cover removal the old plastic bracket slid right out. We used a wooden stake to adjust the position of the engine to remove the bolts after alignment with the holes.

The holes themselves are very small i.e 1 in tops and in no way compromise the integrity of the frame, It would have been nice to have BMW actually design access holes in the frame to access those bolts, just like airplanes need inspection/access plates as mandated by CFR 14 part 23, but that wouild be probably too much to ask.

New bracket was easy to install and bolts were screwed in the same way they were screwed out.

Total for the whole operation: 7 hrs and sweat equity + creativity. Probably a good 4 planning and analyzing. So more like 3 of actual work on the car.

Range is still the same i.e 100 miles give or take and everything works fine except the engine mount which was leaking and broken..

This is actually subject to several recalls in the world i.e EU etc,.. but not in the US.

Dealer quoted me a cool 2.7k since the only replacement mount that exists is for a new bracket made out of cast aluminium vs. plastic for the old one. And the only way to put that together is put the new bracket in and that implies literally dropping the whole engine out for the task.

I refused to pay for it arguing it was an original and flimsy design flaw acknowledged by BMW through their subsequent replacement of said bracket by a metallic one with a reinforced bolt and contacted customer service at BMW regarding the matter. But they argued they have no obligation since my car is out of warranty. They suck and I will consider further options.

Meanwhile me and a friend IA (Inspection Authorization mechanic for Airplanes, the highest ranking certification for airplane mechanics) decided to look at the issue and after I ordered the new bracket, mount and new bolt for the setup (Thanks bmwparts.com!!!) we realized the bracket could potentially be removed from the top of the engine and holes drilled in the frame at strategic locations to access the 2 bolts unreachable by design.

This was all risky and a jump into the unknown of course as I had no clue if the bracket had other hidden attachments and the IA had no experience working on a BEV and could only count on his aeronautical instincts.

There's a lot of craftsmanship and creativity that goes into plane maintenance and it definitely came in handy here.

To drill the 2 holes we inferred the location assuming some movement of the engine would be possible after the mount was removed through the weakest spots in the frame on the left and used a 1 in drill bit for the feat.

After removing all the bolts and supporting the engine using its own jack besides the one allowing for tires and cover removal the old plastic bracket slid right out. We used a wooden stake to adjust the position of the engine to remove the bolts after alignment with the holes.

The holes themselves are very small i.e 1 in tops and in no way compromise the integrity of the frame, It would have been nice to have BMW actually design access holes in the frame to access those bolts, just like airplanes need inspection/access plates as mandated by CFR 14 part 23, but that wouild be probably too much to ask.

New bracket was easy to install and bolts were screwed in the same way they were screwed out.

Total for the whole operation: 7 hrs and sweat equity + creativity. Probably a good 4 planning and analyzing. So more like 3 of actual work on the car.

![300W Car Power Inverter 12V to 110V,PiSFAU DC to AC Car Plug Adapter Outlet with Multi USB[24W USB-C] /USB-Fast Charger(24W) Car Inverter,Car Charger for Laptop Vehicles Road Trip Essentials](https://m.media-amazon.com/images/I/41-KedJShYL._SL500_.jpg)